Part I: Practices to Optimize Nitrogen Fertilizer in Corn Production

Written by Kirk Reese, Blanchard River Demonstration Farms Network Manager

Nitrogen (N) is considered the most essential element needed in all corn cropping systems. It is an inherently complex nutrient primarily due to its dynamic behavior in the soil. It’s also the most limiting nutrient in corn production. There is a high quantity of N in the first few inches of most Ohio soil profiles, however, a very small fraction is in a plant-available form.

The greatest risks with applying additional N fertilizer are loss through different chemical processes that convert it to an unusable form, volatilization as a gas into the atmosphere, and leaching with water down through the soil profile away from the root zone. These N loss pathways can have significant consequences on soil, air and water quality. This article will provide recommendations on how to manage risks associated with N fertilizer in a corn crop using 4R management practices. Part II will be released in a later blog post.

Soil testing

In tandem with a N plan, soil pH and primary nutrients Phosphorus (P) and Potassium (K) should be addressed as reported in the Tri-State Fertilizer Recommendations. Synthetic N fertilizer applications, especially anhydrous ammonia (NH3), tend to be acidifying events and it is important to ensure soil pH is in the ideal range for row crop production, between 5.8 to 7.0 for most Ohio soils. According to research conducted at The Ohio State University, K has a profound interaction with N uptake in the corn crop and should be at or above critical soil test levels as well. N fertilizers are best optimized when applied below the soil surface, surface applications tend to be less efficient and require a higher level of management to minimize N loss.

Pre-plant vs. at-plant N applications

Pre-plant N applications, as the name implies, are applied prior to corn planting in the spring. The advantages of pre-plant applications are more available N when applied closer to planting, and flexibility on early-season side dress or late-season applications.

At-plant N applications or starter fertilizers are applied as a band with the planter. Most N sources used for this type of application are in a liquid form such as 10-34-0 (N-P-K) or 28% Urea Ammonium Nitrate (UAN28). Dry forms can be effective as well, such as diammonium phosphate (DAP) or ammonium sulfate (AMS).

The advantage of both pre-plant and at-plant N is to drive early growth and uniform stand establishment, especially under more challenging conditions shortly after planting. It is important to place N-containing fertilizer in an offset fashion to where the seed is placed. Many fertilizers have a high salt index, that if placed in close proximity, can rapidly move moisture away and “burn” the seed, especially in dry conditions. “Pop up” starter fertilizers placed in-furrow with the seed have a lower salt index and can be used successfully, provided it is applied in small amounts with properly calibrated equipment.

Side dress N applications

Side dress N is applied primarily at the V2 to V6 stage, or when two to six fully developed leaves of corn growth are seen; popular forms are liquid UAN or anhydrous ammonia (NH3). Side dress N is valuable when significant N loss can occur, the risk of N deficiency to the corn crop is high, or when the risk of loss from previous N applications can be reduced.

Seasonally high amounts of precipitation and above-normal temperatures can enhance N loss, so good insurance for N availability is to apply N among pre-plant, at-plant and side dress applications. Whenever feasible multiple applications of N will help better manage the risk of N loss and enable greater precision in matching N rates to yield goals.

Variable rate N applications

Variable Rate N (VRN) applications can be employed where variable soils and yield potential exist. VRN is developed as a prescription that is applied based on yield history and soil attributes. VRN has the greatest value where a high degree of landscape variation is common. The premise is that N rates follow yield potential where lower N rates are recommended in lower producing areas and increase N rate where yield potential is greater. This approach utilizes yield history from georeferenced spatial data captured with a yield monitor on board a grain combine or silage chopper and application equipment capable of varying N rates across the field. VRN is best used where planned in-season N will be applied to the crop.

Late-season N applications

Late-season N applications during reproductive stages of corn growth have gained popularity in recent years, where N is applied aerially in a dry form or with high clearance equipment applied in between corn rows. Research suggests the greatest benefit is when corn grain yield potential is predicted to exceed historical yield levels beyond the current N rate applied. It is important to monitor corn fields for N deficiency to decide if an additional late-season application is warranted.

Positive impact on profits and the environment

A systems approach to N management has the potential to positively impact farm revenue and environmental stewardship, when primary nutrient levels are taken into account, multiple N applications are applied throughout the growing season, and new technology is taken into consideration for your farm.

References:

Culman, S., Fulford, A., Camberato, J., & Steinke, K. Tri-State Fertilizer Recommendations. Bulletin 974. College of Food, Agricultural, and Environmental Sciences. Columbus, OH: The Ohio State University, 2020.

J.W. Johnson, T.S. Murrell & H.F. Reetz, Jr. Balanced Fertility Management: A Key to Nutrient Use Efficiency. Better Crops with Plant Food, Vol. 81, 1997.

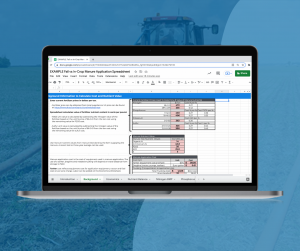

Fall vs In-Crop Manure Application Economic Return Calculator

Fall vs In-Crop Manure Application Economic Return Calculator